![]() METSEC SYSTEM - PURLINS/GIRTS/ACCESSORIES

METSEC SYSTEM - PURLINS/GIRTS/ACCESSORIES

- 350MPA guaranteed minimum yield stress steel

- Z275 galvanized coating

- Design and detailing software and comprehensive

catalogue available on request from Augusta Profiles

Z-SECTION DIMENSIONS The section reference of zed profile 342mm deep and 2.5mm thick = 342.Z.25. The first 3 digits of the section reference are numbers and indicate the depth of section in millimetres (ie 342 equals 342mm deep). The fourth digit is a letter that signifies the profile type (ie Z for Zed Profile). The last two digits are numbered and indicate the material thickness (ie 25 equals 2.5mm). |

|||||||||||||||||||

|

C-SECTION DIMENSIONS The section reference of C-Section 342mm deep and 2.5mm thick = 342 C 25. The first 3 digits of the section reference are numbers and indicate the depth of the section in millimetres (ie 342 equals 342mm deep). The fourth digit is a letter that signifies the profile type (ie C for C profile). The last 2 digits are numbered and indicate the material thickness (ie 25 equals 2.5mm). |

|

||||||||||||||||||

Z-SECTION AND C-SECTION DIMENSIONS

|

SECTION

REFERENCE

|

WEIGHT

KG/LIN MTR Z + C |

TOP

FLANGE

DIMENSION Z |

BOTTOM

FLANGE

DIMENSION Z |

FLANGE

DIMENSION C |

|

|

Z

|

C

|

||||

|

142.Z.14.

|

142.C.14.

|

3.16

|

60

|

55

|

64

|

|

142.Z.16.

|

142.C.16.

|

3.60

|

60

|

55

|

64

|

|

142.Z.20.

|

142.C.20.

|

4.46

|

60

|

55

|

64

|

|

172.Z.14.

|

172.C.14.

|

3.60

|

65

|

60

|

69

|

|

172.Z.16.

|

172.C.16.

|

4.11

|

65

|

60

|

69

|

|

172.Z.20.

|

172.C.20.

|

5.10

|

65

|

60

|

69

|

|

172.Z.25.

|

172.C.25.

|

6.31

|

65

|

60

|

69

|

|

202.Z.14.

|

202.C.14.

|

3.93

|

65

|

60

|

69

|

|

202.Z.16.

|

202.C.16.

|

4.49

|

65

|

60

|

69

|

|

202.Z.20.

|

202.C.20.

|

5.57

|

65

|

60

|

69

|

|

202.Z.25.

|

202.C.25.

|

6.90

|

65

|

60

|

69

|

|

232.Z.16.

|

232.C.16.

|

5.11

|

76

|

69

|

76

|

|

232.Z.20.

|

232.C.20.

|

6.34

|

76

|

69

|

76

|

|

232.Z.25.

|

232.C.25.

|

7.86

|

76

|

69

|

76

|

|

262.Z.16.

|

262.C.16.

|

5.57

|

80

|

72

|

80

|

|

262.Z.20.

|

262.C.20.

|

6.92

|

80

|

72

|

80

|

|

262.Z.25.

|

262.C.25.

|

8.59

|

80

|

72

|

80

|

|

302.Z.20.

|

302.C.20.

|

7.89

|

90

|

82

|

89

|

|

302.Z.25.

|

302.C.25.

|

9.80

|

90

|

82

|

89

|

|

342.Z.20.

|

342.C.20.

|

8.84

|

100

|

92

|

97

|

|

342.Z.25.

|

342.C.25.

|

10.98

|

100

|

92

|

97

|

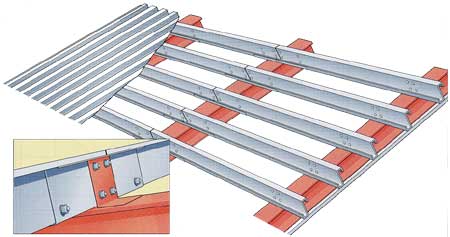

Z-SLEEVED SYSTEM

Roof purlins for buildings with 2 bays or more, up to and including

25° roof pitch.

The sleeved system optimizes the use of steel by incorporating sleeves

at the penultimate rafter with a staggered sleeving arrangement on internal

bays. The sleeved system caters for spans up to 15m depending on the load

to be applied and where the cladding or liner tray offers adequate lateral

support by virtue of its fixing, ie fixed according to the cladding manufacturers

instructions. Consideration must be given to the handling of longer lengths.

To enable the purlin and sleeve to nest together the sleeve is inverted.

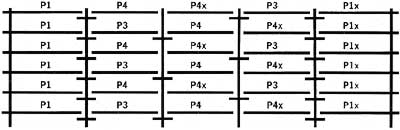

Single Span System

Single span lengths can be supplied to suit individual requirements. Penultimate

rafter connections are sleeved with a staggered sleeving arrangement on

internal bays.

Typical single span arrangement indicating

purlin and sleeve positions.

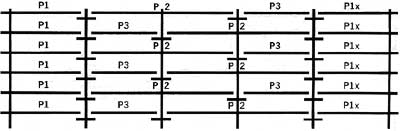

Double Span System

End bay purlins are single span, with double purlins on internal bays.

The maximum span between rafters is 7.5m therefore maximum double span

length is 15m. Consideration must be given to handling the longer lengths.

A joint must always occur at a sleeve position.

Typical double span arrangement indicating

purlin and sleeve positions.

|

Z HEAVY END BAY SYSTEM Z BUTT SYSTEM Z METLAP PURLIN SYSTEM |