| |

Modek

Ampagard PC Technical Product Data

GENERAL

Polycarbonate is one of the newer plastics to be used in the construction

industry around the world. MODEK has been closely involved in the

distribution and manufacture of profiled PC roof sheets during the

past 10 years in South Africa.

The highest grade POLYCARBONATE polymer available from the leading

manufacturers in the world, is used by MODEK. Modern co-extrusion

technology is used in the manufacture of MODEK PC sheets, ensuring

a high product quality and allowing for any transportable length of

sheet to be made.

A layer of highly UV stabilised POLYCARBONATE is co-extruded on the

weathering side of all MODEK PC roof sheets. This layer will not crack

or delaminate, and ensures years of clear performance in the harsh

South African climate.

A range of colours is manufactured with the standards being clear,

white (opal 50) and bronze. Silver (Heat Stop), blue and green are

also available subject to order quantity.

All the generally used profile shapes in South Africa, to match those

of other non-translucent roofing and cladding sheets, are manufactured

by MODEK in any transportable length.

New or additional roofing profiles can be manufactured by MODEK, but

it must be noted that the time and cost incurred is considerable.

Please contact MODEK'S Technical Department for more detailed information.

NOMINAL THICKNESS

The internationally accepted unit of measurement, as used by MODEK,

for PC sheeting is the nominal thickness of the sheet.

This nominal thickness should be established by representative measurements

(by vernier or micrometer) at various points across the full width

of the sheet.

Owing to the inherent variances of tolerance which are experienced

when profiling a thermoplastic extrusion, it will be found that the

actual thickness will vary slightly from one point to another on the

sheet.

MODEK manufactures two nominal thickness specifications:

- 1.25

mm Nominal Thickness

- 1.00

mm Nominal Thickness

A layer

of UV protection PC is co-extruded on the weathering side of all MODEK

PC roof sheets.

1.25 mm Nominal Thickness is deemed to be the Standard Weight Specification

for all industrial installations. This specification will meet the

rigorous conditions found in an industrial environment - particularly

that of deflection under load (positive and negative), handling on

site, spanning capabilities and general robustness of profile.

1.00 mm Nominal Thickness is manufactured as a light weight PC sheet

to be used mainly in those applications where exposure to wind is

less, spanning requirements are less than normal, and generally lighter

domestic-type applications.

The 1.00 mm nominal thickness products are restricted to certain profiles

only. Refer to the profile list for details.

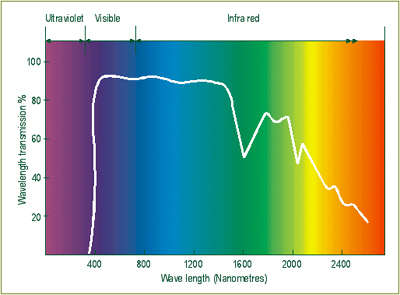

LIGHT AND SOLAR ENERGY TRANSMISSION

Different applications using translucent MODEK PC sheeting call for

varying levels of light transmission. With different colours these

levels change.

Not only does the natural (or visible) light level vary, but the amount

of solar energy (heat) also varies.

Polycarbonate is a thermoplastic with a high degree of clarity. Therefore

the direct transmission of solar energy is considerably higher than

that of a diffused panel. Consideration for the appropriate colour

should therefore be carefully weighed up.

The diagram below depicts the approximate transmission of the various

wavelengths of the light spectrum for a clear PC sheet.

More than 70 % of the heating effect of the sun is carried between

350 and 800 nanometres (generally, the visible light spectrum) and

we can see that these wavelengths are generously transmitted through

a clear MODEK PC sheet - more than 85 %.

Why does heat build up in a room?

As illustrated, a high percentage of the visible short wave radiation

has been transmitted through a MODEK PC clear sheet.

This radiation is absorbed by surfaces inside the room, and these

surfaces become heat radiators. The heat emitted from these "radiators"

is long wave radiation which is not so readily transmitted out of

the room through the MODEK sheet. The result is that the trapped heat

builds up in the room. This is also known as the "greenhouse

effect".

An effective method of combating heat build-up in a room is to have

good through ventilation. This can also be improved by selecting the

most appropriate MODEK PC roof sheet.

The table below shows the various percentages of transmitted light

and solar energy, and also that amount of light and solar energy which

is reflected and absorbed by the different coloured MODEK PC sheets.

ColorQUEST Colorimeter Test Results

MODEK PC Translucent Roof Sheets

| MODEK

PC ROOF SHEET TINT |

CLEAR |

BLUE |

GREEN |

OPAL

50 |

BRONZE |

OPAL

10 |

| |

| VISIBLE

SPECTRUM (380 nm - 700 nm) |

|

% Light Transmission |

90 |

65 |

40 |

50 |

40 |

25 |

|

% Light Reflectance |

13 |

10 |

10 |

42 |

8 |

74 |

| |

| SOLAR

ENERGY (350 nm - 2100 nm) |

|

% Rejected |

13 |

26 |

41 |

41 |

40 |

67 |

|

% Direct Transmission |

87 |

68 |

47 |

57 |

47 |

31 |

|

% Direct Reflectance |

11 |

8 |

8 |

34 |

7 |

63 |

|

% Absorption |

3 |

24 |

44 |

9 |

46 |

7 |

|

% Total Transmission |

88 |

74 |

59 |

59 |

60 |

33 |

| |

| SHADING

COEFFICIENT |

1.00 |

0.86 |

0.68 |

0.68 |

0.69 |

0.37 |

Notes:

- Shading

coefficients are used for comparing solar heat transmission properties

of different glazing materials to that of clear float glass 3

mm to 4 mm thick, the glass being given a value of 1. To be used

for comparative purposes only.

- For

practical purposes, MODEK PC sheets do not transmit harmful UV

rays.

Should

there be any further requirements regarding the light and solar energy

transmission of MODEK PC roof sheets, contact MODEK'S Technical Department.

MODEK HEAT STOP

MODEK Heat Stop is an innovative development in polycarbonate translucent

roof sheeting. This product effectively eliminates 60% of the radiated

heat of the sun, resulting in a cool shaded environment.

MODEK Heat Stop is a polycarbonate profiled extrusion, manufactured

in South Africa, which has a co-extruded layer of UV stabilised surface

protection on the weather side. Microscopic reflective particles are

incorporated in the core material which create the silver colour and

the reflective qualities of the product.

If an application for a translucent roof sheet or skylight requires

a minimum heat build-up under the natural light panel - MODEK offers

a polycarbonate solution. It should be remembered, however, that a

lower level of light transmission is achieved with MODEK Heat Stop.

The appropriate surface area of translucent roof sheets must therefore

be used to achieve the required interior light levels.

MODEK Heat Stop offers the following properties:

- All

the excellent physical properties of polycarbonate.

- UV

surface protection on weather side.

- Exciting

new colour - silver.

- 20

% light transmission.

- It

is available in 1 mm and 1.25 mm profiles:

IBR

Corrugated

Nurib

Grecca

- Price

- the same as the normal tint price.

ColorQUEST

Colorimeter Test results

| MODEK

PC SHEET |

MODEK

Heat Stop |

| |

| VISIBLE

SPECTRUM (380 nm - 700 nm) |

|

% Light Transmission |

22 |

|

% Light Reflectance |

32 |

| |

| SOLAR

ENERGY (350 nm - 2100 nm) |

|

% Rejected |

60 |

|

% Direct Transmission |

27 |

|

% Direct Reflectance |

27 |

|

% Absorption |

46 |

|

% Total Transmission |

40 |

| |

| SHADING

COEFFICIENT |

0.46 |

Notes:

- Shading

coefficients are used for comparing solar heat transmission properties

of different glazing materials to that of clear float glass 3

mm to 4 mm thick, the glass being given a value of 1. To be used

for comparative purposes only.

- For

practical purposes MODEK Heat Stop does not transmit harmful UV

rays.

WEATHERABILITY

MODEK PC roof sheeting is manufactured using modern co-extrusion technology

to create a highly UV stabilised weathering surface on the sheet.

This UV layer will not crack or delaminate, and ensures years of trouble-free

performance in the harsh South African weather conditions.

As with almost all plastics, UV attack from the sun will, over a period

of time, adversely affect MODEK PC roof sheets. This process is called

photodegradation.

What occurs during this process is the following:

The aggressive short wavelength UV rays are absorbed into the polymer.

They "excite" the chemical molecular bonds, causing them

to separate, resulting in a slight yellowing and a reduction of physical

properties such as tensile strength and impact resistance.

This process is significantly reduced in the MODEK PC sheet because

of the excellent protection offered by the UV co-extruded layer which

incorporates UV stabilisers and UV absorbers. Over a prolonged period,

a slight yellowing or hazing will be detected in a MODEK PC sheet.

With outside exposure in normal conditions in South Africa, it is

expected that a clear MODEK PC sheet with UV protection will not increase

in yellowness more than 9 yellowness index units within ten years

from date of sale.

The determination of the yellowing index will be made on samples subjected

to pre-test cleaning and conditioning according to MODEK's test procedures,

and the yellowness index shall be determined according to ASTM D-1925-70

as measured with Hunter Colour-Quest colour Spectrophotometer.

A MODEK PC sheet will retain virtually all its physical properties,

and remain structurally sound over this period of time, under normal

conditions.

CORROSION AND CHEMICAL RESISTANCE

MODEK PC sheets will resist chemical attack and corrosion in most

industrial and marine environments.

Tests have found the following:

- MODEK

PC is highly resistant to corrosion and high concentrations of

mineral acids, many organic acids, oxidising and reducing agents,

neutral and acid salt solutions, many oils and fats, saturated

aliphatic and cyclo-aliphatic hydrocarbons and alcohols.

- MODEK

PC is not resistant to strong acids and alkalis, methyl alcohol,

aromatic hydrocarbons and chlorinated hydrocarbons nor to lengthy

immersion in hot water.

- MODEK

PC must not be used in conjunction with plasticised PVC. This

will result in stress corrosion cracking and cause damage to the

MODEK PC sheet.

- MODEK

PC sheets are ideal for coastal applications.

The resistance to chemical attack varies with a wide range of chemicals,

detergents, polishes and cleaning agents. This resistance chart refers

to certain chemicals and the reaction of PC under certain conditions.

Please refer to MODEK'S Technical Department should you have a query.

+ resistant

- non-resistant

| CHEMICALS

|

6

days / 23 °C |

|

Acetic acid, 10 % in water |

+ |

|

Hydrochloric acid, 10 % in water |

+ |

|

Sulphuric acid, 10 % in water |

+ |

|

Nitric acid, 10 % in water |

+ |

|

Phosphoric acid, 1 % in water |

+ |

|

Citric acid, 10 % in water |

+ |

|

Sodium carbonate (soda), 10 % in water |

+ |

|

Sodium chloride, saturated / aqueous solution |

+ |

|

Sodium nitrate, 10 % in water |

+ |

|

Ammonium nitrate, 10 % in water / neutral |

+ |

|

Iron (III) chloride, saturated / aqueous solution |

+ |

|

Potassium hydroxide 1 % in water |

- |

|

Sodium hydroxide (caustic soda), 1 % in water |

- |

|

Ammonia, 0.1 % in water |

- |

|

Acetone |

Swells |

|

Benzine (free from aromatic compounds) |

+ |

|

Benzene |

Swells |

|

Butyl acetate |

- |

|

Chloroform |

Dissolves |

|

Dibutyl phthalate |

- |

|

Diethyl ether |

- |

|

Dimethylformamide |

Dissolves |

|

Dioctyl phthalate |

- |

|

Dioxane |

Dissolves |

|

Ethanol (pure) |

+ |

|

Ethylene glycol, 1:1 with water |

+ |

|

Ethylene chloride |

Swells |

|

Ethyl acetate |

Swells |

|

Ethylamine |

- |

|

Glycerine |

Reacts |

|

Isooctane (2.2.4-trimethyl pentane), pure |

+ |

|

Isopropanol (pure) |

+ |

|

Hexane |

+ |

|

Methanol |

- |

|

Methylamine |

Reacts |

|

Methylene chloride |

Dissolves |

|

Methyl ethyl ketone |

Swells |

|

Ozone, 1 % in air |

- |

|

Paraffin, paraffin oil, (Vaseline), pure / free from aromatic

compounds |

+ |

|

Perchloroethylene |

- |

|

Perhydrol (hydrogen dioxide), 30 % in water |

+ |

|

Propane |

+ |

|

n-propanol |

- (30 °C) |

|

Styrene |

- |

|

Silicone oil |

+ |

|

Carbon tetrachloride |

Swells |

|

Tetrachloroathane |

Swells |

|

Trichloroethylene |

Swells |

|

Tricresyl phosphate |

- |

|

Triethylene glycol |

+ |

|

Xylene |

Swells |

PHYSICAL AND MECHANICAL PROPERTIES

| Tensile

Strength |

72 MPa - ASTM D-638 |

| Flexural

Strength |

92 MPa - ASTM D-790 |

| Modulus

in Flexure |

2400 MPa - ASTM D-790 |

| Thermal

Movement |

Coefficient of linear expansion (clear) 67 X 10-6m/°C. - ASTM

D-696 |

| Water

Absorption |

0.36% by mass after 24 hours at 20°C - ASTM D-570 |

| Hardness

|

80 (°Shore D) |

| Drop

Dart Impact Strength |

25 Nm (Gardner) |

| Thermal

Conductivity |

0.2. W/mK - ASTM C-177 |

| Flammability

|

V2 when tested to UL94 ratings. Whilst MODEK PC sheets do burn,

they are self-extinguishing and will not promote fire or assist

spread of flame. |

Note: The very high impact resistance of MODEK PC sheets makes them

virtually unbreakable, and therefore makes them particularly suitable

for use in high risk areas where damage from hail, high wind loads

or vandalism is likely.

MODEK PC PROFILES

Polycarbonate Profiles

Notes:

- All

sheets have a co-extruded UV protection layer on weather side.

- All

dimensions are nominal.

- Other

profiles available subject to order quantity.

|

|