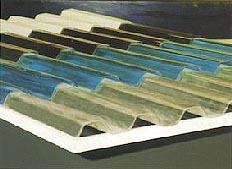

| PANEL ROVING

990 Panel Roving

990 Panel roving is manufactured from E Glass and gathered without mechanical

twist and wound into a cylindrical package. 990 Panel Roving has a silane sizing system designed to be

highly compatible with polyester resins that are used with continuous production equipment

for the manufacture of translucent sheeting as well as with filled resin systems. Typical

refractive index for 990 panel rovings is 1,5569.

General Information

- Yield: 2400 Tex (nom.)

- Roving mass: 13 kg (nom.)

- Moisture: 0,1% (max.)

- Tex deviation: ±10%

- Flexural strength: 588 MPa (min.)

- Fibre diameter: 11 micron (nom.)

- No. of ends: 120 (nom.)

Packaging

990 Panel roving is individually wrapped in a Polythene sleeve and packed into a cardboard carton.

Application Application

990

Panel roving can

be readily chopped into lengths between 25 mm and 75 mm. The soft nature of 990

Panel roving means

that the chopping equipment to be used must be suitable for this type of roving.

990 Panel roving sizing system contains a suitable anti-stat agent to facilitate multiroving feeding from

suitable creels. 990 Panel rovings are not suitable for choppergun applications.

Approval

990 Panel roving is manufactured to the requirements of the South African Bureau of Standards

specification SABS 1446-1988.

Storage

It is recommended that fibreglass be kept at a minimum temperature not exceeding 25°C

and a relative humidity not exceeding 65%.

Owens Corning South Africa reserves the right to change this specification without notice. |