PROCESS INSULATION

APPLICATION GUIDE

Corrosivity of Rockwool Insulation

Glasswool and Rockwool products have no corrosive action on the standard metals, e.g. iron, steel, copper, zinc,

aluminium. Generally, the degree of corrosiveness/stress corrosion cracking of austenitic stainless steel is regarded as a function of the quantity of leach- able/water soluble free chloride ions available in the product. However, there are other factors determining the non-corrosive nature of Rockwool products.

There are two test methods, currently being used to determine the non- corrosiveness of mineral fibre insulation, which are more extensive than only ascertaining the water leachable chloride content.

- ASTM-E692-71 and

- Standard Method RDTM-121T of US Atomic Energy Conversion Military Specification MIL-1-24244 (Ships) - described as the

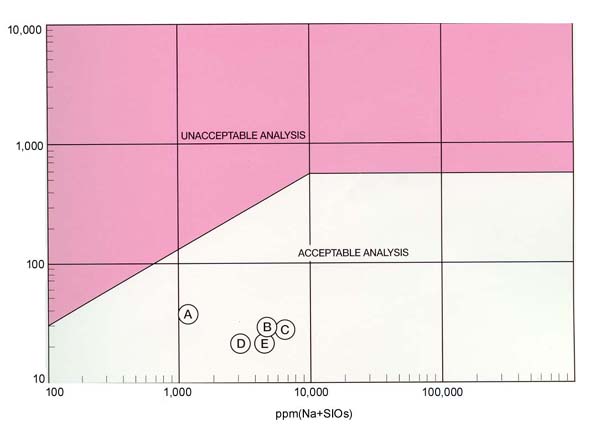

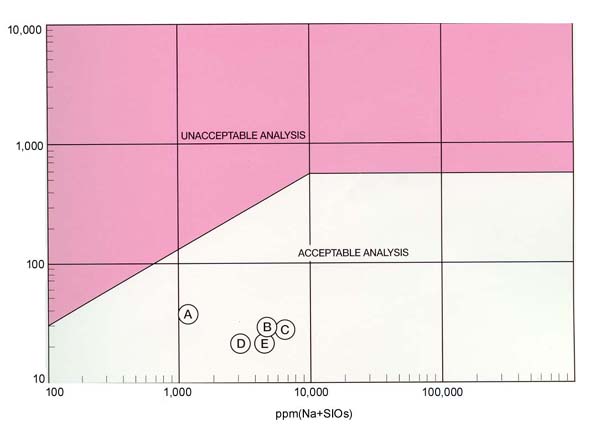

Westinghouse-Karnes method. The acceptability conditions in this test are comparatively severe because of the intended application in nuclear plants. The chemical analysis of chlorides, fluorides and sodium silicates present in the insulation are plotted on the Karnes diagram, which has acceptable and unacceptable analysis zones. The sodium and silicate ions have a corrosion inhibiting action on the chlorides and fluorides, which is important.

The analyses of Owens Corning South Africa Rockwool products fall within the acceptable zone of the Karnes diagram. And, thus, they can be considered as non-aggressive and also as non-corrosive, unless influenced by external factors.

It should be noted that chlorides are common to most environments and can be deposited on the surface of the insulation from the air or even from operative hands. In the presence of water these chlorides can migrate through the insulation and can be concentrated on the insulated surface. Thus, care should be taken during the installations of any insulation system.

Typical Results

|

Sample

identification |

Chloride content as

Cl; mg/kg |

Fluoride content as F; mg/kg |

Sodium content as Na, % (m/m) |

Silica content as SiO3, % (m/m) |

| Loose wool Batch No. W0070 |

0,76 |

29,5 |

0,011 |

0,092 |

| 0,76 |

29,4 |

0,011 |

0,091 |

| lnsulmatt Batch No. M0083 |

1,92 |

11,5 |

0,023 |

0,11 |

| 1,88 |

11,6 |

0,022 |

0,11 |

| Insulboard Batch No. B0048 |

0,37 |

21,3 |

0,042 |

0,10 |

| 0,40 |

21,0 |

0,042 |

0,10 |

| lnsulfelt Batch No. F0018 |

1,52 |

12,5 |

0,020 |

0,097 |

| 1,40 |

12,9 |

0,020 |

0,098 |

| Pipe section Batch No. P0441 |

4,23 |

10,6 |

0,039 |

0,094 |

| 3,92 |

10,8 |

0,039 |

0,097 |

Acceptability of insulation based on the leachable (CI + F) and the leachable

(Na + SiO3) analysis.

A = Loose wool

B = Insulmatt

C = Insulboard

D = Insulfelt

E = Pipe Section

|

|