|

|

| |

|

|

| |

Armourplate Armourplate

|

|

| |

The safety attributes

of ARMOURPLATE are generally recognised. However, its strength

permits its use in a wider range of applications.

ARMOURPLATE is manufactured from either ClearVue (Float)

or DecorVue (Patterned Glass) by subjecting it to a process

of heating and rapid cooling. This process sets up high

compressive stresses at the surfaces with balancing tensile

stresses in the centre. These balanced stresses give ARMOURPLATE

its increased strength while retaining the general appearance

of ordinary glass.

ARMOURPLATE is at least five times stronger than ordinary

glass. Because of its increased strength, ARMOURPLATE is

the ideal material for structural glazing, allowing designers

greater flexibility and scope.

ARMOURPLATE can withstand extremes of heat and cold. Up

to 300 °C and down to -200 °C. This resistance to severe

temperature differentials allows ARMOURPLATE to be used

where ordinary annealed glass would be likely to fracture

due to high thermal stresses.

ARMOURPLATE is available in a wide range of glass types

in varying thicknesses which include:

ClearVue: Clear, Antisun Grey, Antisun Bronze and

Forest Green.

Patterned Obscure: A range of DecorVue patterns available

on application.

Coated Glass: Pyrolitic coated glass available on

request.

All doors and sidelights, framed or unframed (refer Technical

Information sheets for details on ARMOURPLATE doors)

Sliding or patio doors

Glazed panels in doors

Balcony enclosures

Shower doors and bath enclosures

Barriers between different levels

Low level glazing

Balustrades (refer Technical Information sheets)

For hail resistance

Where additional strength for wind loading is required

Where glass is subjected to high thermal stress (e.g unfavourable

shadow patterns or poor back ventilation)

Table tops

Squash and racket ball courts - PFG Building Glass is

the only South African supplier approved by the World Squash

Federation

The

maximum glass size that can be processed is 4000x 2000mm

subject to a weight restraint of 240kg. The maximum sizes

indicated are not necessarily recommended as this is dependent

on application and design load considerations.

|

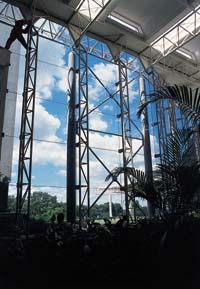

Iscor

Building, Pta, Boogertman Krige |

Viewall

Squash Court |

First

National Bank, Sandton - Louw, Apostelellis & Bergenthuin |

|

| |

|

|

| |

|

|

| |

|

|

Transparent

float glass - clear

|

|

Nominal

thickness

|

Normal

maximum sizes

|

Approximate

kg/mē

|

|

4

mm

|

3700

x 2000

|

10

|

|

5

mm

|

3210 x 2000

|

12.5

|

|

6

mm

|

3700

x 2000

|

15

|

|

8

mm

|

3210

x 2000

|

20

|

|

10 mm

|

3210

x 2000

|

25

|

|

12

mm

|

3210

x 2000

|

30

|

|

15

mm

|

3210

x 2000

|

37.5

(240 kg max)

|

|

19

mm

|

3210

x 2000

|

47.5

(240 kg max)

|

|

Transparent

float glass - tinted

|

|

Nominal

thickness

|

Normal

maximum sizes

|

Approximate

kg/mē

|

|

4

mm

|

3180

x 1830

|

10

|

|

6

mm

|

3180

x 2000

|

15

|

|

10

mm

|

3180

x 2000

|

25

|

|

12

mm

|

3180

x 2000

|

30

|

|

Patterned obscure glass - clear and amber

|

|

Nominal

thickness

|

Clear

|

Amber

|

Cotswold

Amber

|

Approximate

kg/mē

|

|

4

mm

|

2100

x 1325

|

2150

x 1400

|

2150

x 1250

|

10

|

|

6

mm

|

2100

x 1325

|

2150

x 1400

|

2150

x 1250

|

15

|

It

is imperative that PFG Building Glass be consulted timeously

regarding the lead times for supply of product.

To

assist in optimising design and specifications, PFG

Building Glass offers a technical advisory service covering

most appropriate product for each application; economy,

thermal stability, Building Regulations, guarantees

and local and international product standards. For maximum

benefit to the project this should ideally commence

before working drawings begin.

Our commitment to the ISO 9000 Quality

Management System means that our customers have confidence

in the ability of PFG Building Glass to deliver the

desired quality, consistently. |

ARMOURPLATE

meets the requirements of the South African National

Building regulations.

|

|

|

|

|